5 in 1 Vacuum Laminating and Air Bubble Removing Machine for LCD Screen Up to 7 inch

- SKU:

- MBEQ011

- Condition:

- New

- Availability:

- Usually ships in 24 hours

Description

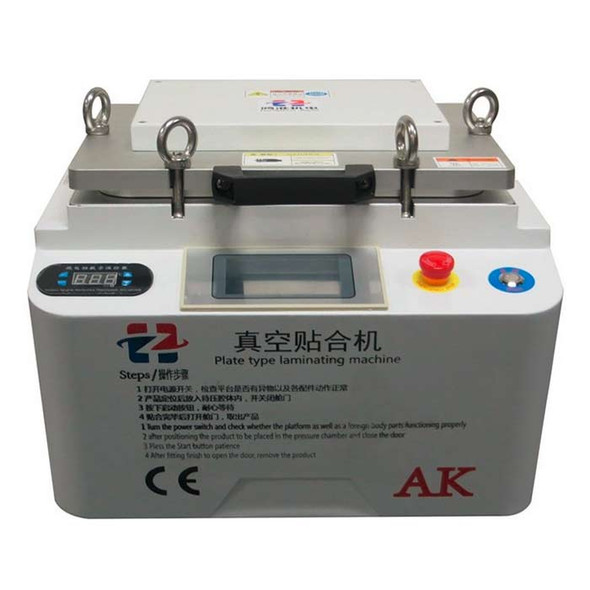

5 in 1 Vacuum Laminating and Air Bubble Removing Machine for LCD Screen Up to 7 inch

No Compressor and Vacuum Pump Needed, Vacuum OCA Laminating and Air Bubble Removing Process can work Separately and Simultaneously!

This equipment is to do both the laminating process and the bubble removing process, which is the last main steps for repairing ( refurbishing ) explosion LCD sceen of smartphones or tablets. When quite a few screens to be refurbished, you may to do the OCA laminating process and the bubble removing between polariser film and LCD glasses at the same time.

It's very suitable for OCA laminating and bubble removing process of the capacitive touch screen cover plate (Cover Lens) and functional Glass Sensor (Glass), the touch screen (Touch Panel) and liquid crystal module (LCD Panel). Sure you can also use it to other areas of membrane OCA laminating process and bubble eliminating process.

Some popular mobile phones and tablets the machine to fix as below:

- Apple iphone 6, iphoen 6s, iphone 5, iphone 5s, iPad 2

- Samsung Galaxy S3, S4, S5, S6

- Samsung Galaxy Note 1, Note 2, Note 3, Note 4, Note 5

Features:

- The machine owns smart touch screen, which can display and set parameters by touching.

- No mould, also can set to be no defoaming or defoaming assisted type to apporve the output

- No installation, can be working directly when plug in

- Don't need other auxiliary equipment, such as vacuum pump, air compressor

- Used standard 6063 aluminum alloy for lamination, durable, anti-corrosion and no deformation

- Debubblers cavity materials is 304 15mm stainless steel, safe

- Fitting and debubblers can be operated simultaneously, improve efficiency

- The components are imported from Japan

- Simple one-touch operation

- Japan temperature control, temperature can be accurate to + / - 1C

- Intelligent constant pressure, laminating and defoaming mode automatically switch

- Flat-plate form laminating, stable and even pressure, no bubble, no indentation, easy transportation

Product Parameters:

- Power: 800W

- Power Supply: AC220 or AC 110

- Work Environment: 20-30℃, Clean and Dust-free

- Laminating: Flat Type Lamination

- Production Efficiency: 90s/1pcs(Separated lamination type), 1H/80pcs (defoaming assisted type)

- Heating Method: Constant temperature

- Applicable Size: 7 inch and below

- Size of Equipment: 535 X 425 X 355 mm

- Weight of Equipment: about 65KG

Defoaming parameters:

- Cavity size: H 180mm

- Diameter: 120mm (put into 15pcs 7-inch screen one-time)

- Working temperature: Suggested set 35℃ – 45℃ (can be adjustable according to different OCA temperature)

- Defoaming time: Suggested 8 - 10 minutes (it is best)

Checking and para position:

- Check whether the tray is smooth

- Check whether there is foreign body on the silicone pad

- Use mould to align

- Align the LCD and silicone pad (LCD is on the silicone pad,and the IC is out of the silicone pad.)

- Put the aligned LCD assembly on the operating platform

- If the cellphone with long flex cable, let the flex cable be outside of the operating platform, and slightly curved upward.

Certificate: CE Certificate

Warranty: 1 Year Warranty

Shipping Packing: Wodden Box Packing